Elasti Prints® Screen Printed Transfers

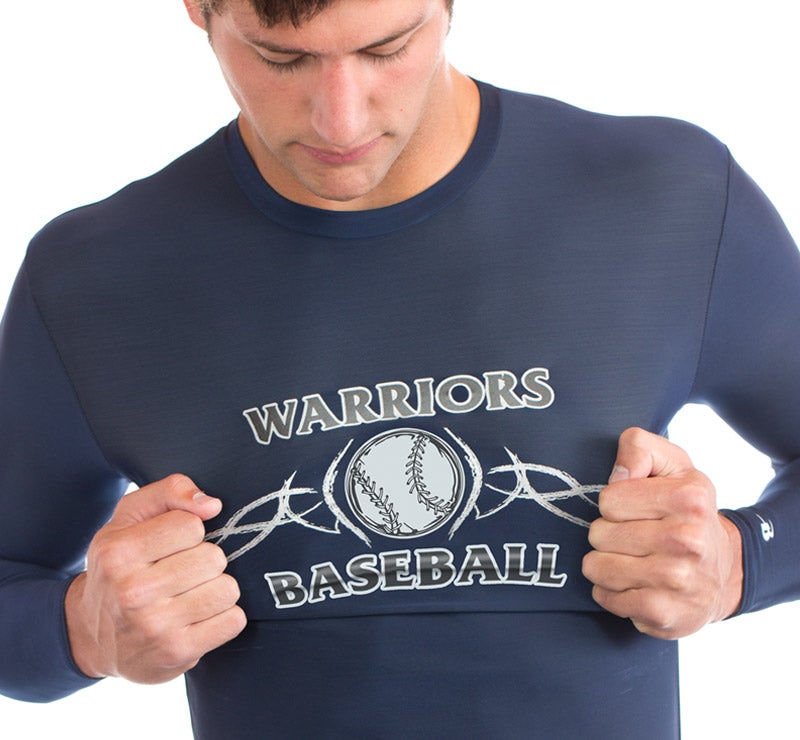

Ideal for heat-sensitive, stretchable polyester fabrics.

Designed to apply at low heat for use on performance fabrics, such as Under Armour® and other moisture-wicking apparel.

- Ideal for performance apparel.

- Applies at low temperature to prevent melting or scorching of heat-sensitive fabrics.

- When using 2 or more ink colors, a common backing color is required (one of the colors will need to outline all the other colors)

- Available in 70 stock colors

- Recommended Fabrics: 100% polyester

- Get instant pricing with the Screen Print Price Calculator.

Get Started

Start Designing in Easy View Send Us Your ArtworkArtwork Guidelines

Screen printed transfers require vector artwork.

You can send us vector artwork and we can print it as is or with adjustments.

You can send us raster (non-vector) artwork that we will redraw/convert to vector.

Send us the best artwork that you have.

1. Size: Standard sheet size is 11.25″ x 14″.

Jumbo sheet size available at 12.5" x 17.5".

Although not required, it is a good idea to send us your file at the size you want it printed.

2. Text: Convert all text to curves/outlines before sending.

3. Colors: We use spot colors for screen printing. You can use spot colors when creating art, but it is not required. Use consistent colors in your file.

4. Line Thickness: minimum of .012″ for printed areas.

5. Show-Thru Thickness: minimum of .04″ for non-printing areas

6. Special effects: Some special effects such as fades and shading can’t be produced with screen printing. Consider full color transfers if your art contains these.

7. Multi-Color: When using two or more ink colors, one of the colors will need to outline all the other colors for a common backing color.

We accept the following file types:

.AI, .JPE, .JPEG, .JPG, .PDF, .PNG, .PSD, .SVG, .TIF, .TIFF, .TXT

- Adobe Illustrator® - all versions

- Adobe Acrobat® (PDF) - all versions

- Jpgs (photos) - we will redraw these types of files in a vector format

- Photoshop® - all versions

Tips / Application

Pre-Production

Please check transfers carefully before heat-applying.

Set Temperature

Set the press to 290°F

Pre-Heat Garment

First, place the garment on platen, heat press for 3-5 seconds or until there is no more steam to remove wrinkles and moisture. Ensure there are no obstructions such as buttons, pockets, or seams. If there are, raise only the print area with a Print Perfect Pad.

Position & Press

Place the transfer on the garment so that the ink side is facing down. Close the heat press and apply for 15 seconds.

Peel Cold

Open the press and remove the shirt. Allow to cool completely to the touch. (This may take several minutes to cool completely.)

Peel the carrier in a smooth, even motion.

Note: The recommended time, temperature, and pressure settings are for Stahls' Hotronix® heat press machines. Settings on other heat presses may vary.

-

Time

15 Seconds

-

Temperature

290ºF

-

Pressure

Medium/Firm 6-8 (60-80 psi)

-

Peel

Cold

Questions

I also need numbers for my stretchy polyester fabric; do you have Elasti Prints numbers?

Yes - Champ Pro numbers use the Elasti Prints® formula.

What do you recommend for printing on non-woven recycled materials (tote bags) and non-woven polypropylene totes?

Our Elasti Prints® work great on polypropylene tote bags.